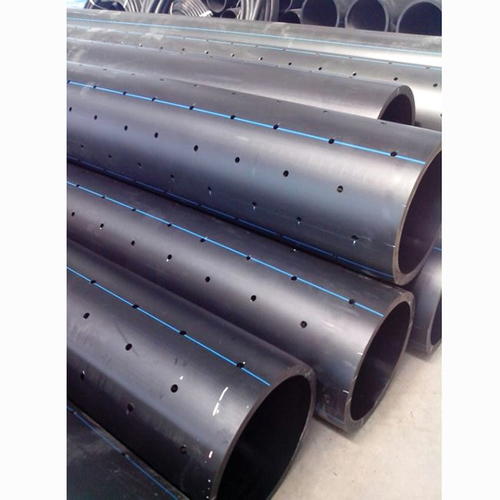

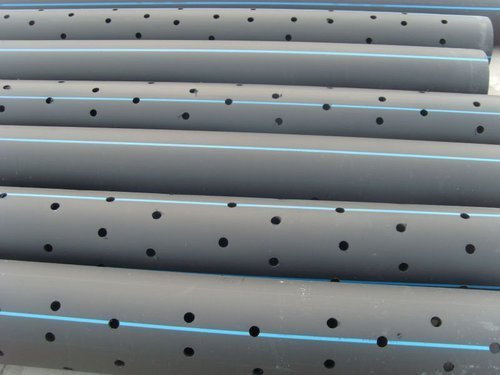

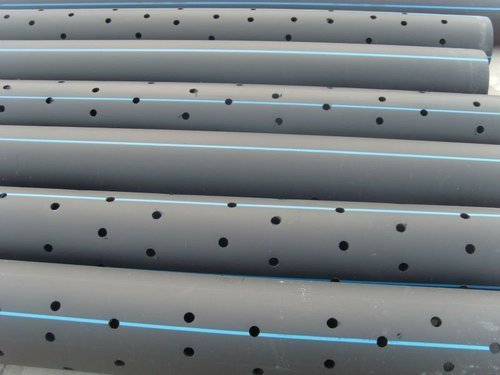

HDPE Perforated Pipe

Product Details:

- Pressure 2.5 kg/cm2 to 20 Kg/cm2 kgf/cm2

- Life Span 50 yrs

- Diameter 20OD TO 630OD Inch (in)

- Corrosion Resistant YES

- Shape ROUND

- Application Sewerage and Drainage systems , Industrial effluent disposal systems , Irrigation/ Agriculture

- Usage UNDERGROUND, WATER SUPPLY

- Click to View more

HDPE Perforated Pipe Price And Quantity

- 500 Meter

- 2.0 INR/Meter

HDPE Perforated Pipe Product Specifications

- Sewerage and Drainage systems , Industrial effluent disposal systems , Irrigation/ Agriculture

- UNDERGROUND, WATER SUPPLY

- 2.5KG TO 20KG

- HDPE PIPE

- HDPE

- 1 TO 10 Inch (in)

- 1 Kilograms (kg)

- Butt Fusion

- HDPE PERFORATED PIPE

- 20mm TO 630mm Millimeter (mm)

- Light Weight, Long lasting, Heavy Duty

- A1

- Elbows, Tees, Reducers, Couplings, Flanges, Caps Nipples, Valves

- 2.5KG TO 20KG

- 6/12/Coil Centimeter (cm)

- 2.5 kg/cm2 to 20 Kg/cm2 kgf/cm2

- 50 yrs

- 20OD TO 630OD Inch (in)

- IS 4984:1995, IS 14333:1996, IS 14151(Pt-2):2008, DIN 8074, DIN 8075, ISO 4427

- YES

- 5 yrs

- ROUND

- Black with Blue strips

HDPE Perforated Pipe Trade Information

- mundra

- Cash Advance (CA), Cash in Advance (CID), Letter of Credit at Sight (Sight L/C), Letter of Credit (L/C)

- 800000 Meter Per Year

- 1 Week

- No

- Free samples are available

- Packing details for Elegant HDPE Perforated (High-Density Polyethylene) pipes can vary depending on the pipe size, length, pressure rating, and manufacturer. However, there are standard practices commonly followed in the industry to ensure safe transportation and storage. HDPE Perforated Pipe Packing Details: 1. Bundling: Small diameter pipes (e.g., 20mm to 110mm) are usually bundled in coils. Common coil lengths: 50m, 100m, 200m, up to 500m depending on the diameter. Bundles are tied using plastic straps or polypropylene ropes. Wrapped in LDPE stretch film or woven bags to protect from UV and damage. Larger diameter pipes (e.g., >110mm) are straight lengths. Typically 6m or 12m straight pipes. Packed in bundles of several pipes per bundle (number depends on pipe diameter). Bundles are secured with nylon or metal straps. Ends are often capped with plastic end caps to prevent dust and damage. 2. Wooden Supports or Pallets: For export or long-distance transportation, wooden crates or pallets may be used to stabilize the bundles. Blocking and bracing is done to avoid shifting during transit. 3. Marking and Labeling: Each bundle or coil is labeled with: Pipe size (OD, wall thickness) Pressure rating (PN2.5, PN10, PN16) Material grade (PE63, PE100, PE80) Standard followed ( ISO 4427, DIN 8074) Manufacturing date, batch number, and manufacturer's name/logo 4. Protection: UV-resistant wrapping (especially for outdoor storage). Pipe ends sealed or capped to avoid contamination. 5. Container/Truck Loading: Pipes are stacked carefully in layers to optimize space. Heavy pipes at the bottom, lighter on top. Use of dunnage to separate layers and avoid deformation.

- Australia, South America, Eastern Europe, Africa

- All India

- IS 4984:1995, IS 14333:1996, IS 14151(Pt-2):2008, DIN 8074, DIN 8075, ISO 4427

Product Description

Our entity is the topmost name in manufacturing and exporting of an excellent range of HDPE Perforate Pipe. These perforated pipes are extensively used in agriculture industry for the removal of unnecessary water from land. In addition, these pipes are also used for preserving the foundations of buildings and constructions. In underground applications, the HDPE Perforate Pipe offers great advantage as it has high wear and abrasion resistance with ability to withstand aggressive chemicals and biochemical effects.Features:

- High compressive strength

- Can withstand aggressive chemicals

- Sturdy and durable

HDPE Perforated Pipes:

Elegant HDPE Perforated Pipe is used to accelerate the removal of subsurface water in soils or to allow storm water to percolate into the soil. HDPE pipes are produced with slots or perforations to collect and convey subsurface water to a more favorable location for discharge. The perforations shall be approximately circular and arranged in rows parallel to the axis of the pipe. Elegant HDPE perforated Pipes are available in Full / Half / 1/3rd perforation. The locations of the perforations shall be in the valley of the outside surface.

Applications:

- Golf courses

- Athletic fields

- Sub surface drainage system for roads/highways

- Storm water drainage

- Detention/retention systems

- Agricultural drainage projects

- Sub surface drainage system for draining excess water from lawns/gardens/agricultural farms

- Sub surface drainage for large construction water logged sites

- Collection of methane & leachate gas from landfill dump

- Sea water intake assembly

- Airport runway sub surface drainage system.

FAQs

- What is HDPE perforated pipe?

HDPE perforated and slotted pipe is the preferred material for water drainage, leachate systems, cable protection, ducting, and landfill gas dissipation.

- What is the use of perforated pipes?

Perforated pipe systems can be thought of as long infiltration trenches or linear soakaways designed for both stormwater conveyance and infiltration. They are underground stormwater conveyance systems designed to reduce contaminant loads to receiving waters by attenuating runoff volume.

- How deep should perforated pipe be?

The trench should be about 2 feet deep and sloped downward in the direction you want the water to flow. Cut any roots that are growing in your French drain.

- How does perforated pipe carry water?

Perforated pipe, on the other hand, is identical in shape to solid pipe, but has holes or slots cut into it along its entire length, allowing water to enter and exit freely.

- Is perforated pipe good for drainage?

A perforated pipe has small slots or holes that allow water to easily exit or enter. Because of its ability to absorb and drain water, this type of pipe is commonly used for underground drainage systems and other outdoor applications.

Superior Strength and Wide Application

Engineered from quality HDPE material, these perforated pipes excel in challenging environments, supporting pressures from 2.5kg to 20kg/cm. Widely used for sewerage, industrial drainage, agricultural irrigation, and disposal of effluents, they offer dimension flexibility (20mm to 630mm), making them suitable for various scale installations.

Designed for Endurance and Efficiency

HDPE Perforated Pipes are characterized by their longevity, light weight, and resistance to corrosion. Certified to meet IS and DIN standards, they provide secure butt fusion connections and come with essential fittings like elbows, tees, and couplings. Their long 50-year lifespan ensures reliable service while minimizing maintenance.

FAQs of HDPE Perforated Pipe:

Q: How are HDPE perforated pipes installed in underground water supply systems?

A: HDPE perforated pipes are installed using the butt fusion technique, which provides a durable, leak-proof joint. The installation process typically involves trench preparation, pipe laying, welding or fitting using recommended couplings or flanges, and backfilling to secure the pipes underground.Q: What are the main benefits of using HDPE perforated pipes for drainage and effluent disposal?

A: The primary benefits include their high resistance to corrosion, ability to withstand varying pressures (2.5 to 20 kg/cm), and long-lasting performance (up to 50 years). Their lightweight construction makes handling and installation easier, while their flexibility helps adapt to different site requirements.Q: When should HDPE perforated pipes be chosen over conventional piping for industrial and agricultural applications?

A: Choose HDPE perforated pipes when you need a robust, corrosion-resistant solution capable of handling high-pressure fluids and harsh chemicals, such as in industrial effluent systems or large-scale irrigation. Their compliance with multiple standards ensures safety and reliability.Q: Where can HDPE perforated pipes be effectively used?

A: These pipes are ideal for use in underground sewerage and drainage networks, water supply infrastructure, industrial effluent disposal systems, and agricultural irrigation facilities. Their versatility and resistance to corrosion allow installation in varied soil and water conditions.Q: What fittings and accessories are available for HDPE perforated pipes?

A: A wide range of fittings are compatible, including elbows, tees, reducers, couplings, flanges, caps, nipples, and valves. These accessories facilitate customized layouts and ensure leak-proof connections in both new installations and repairs.Q: What is the lifespan and warranty coverage of HDPE perforated pipes?

A: These pipes have a remarkable operational lifespan of up to 50 years when installed correctly and maintained, and they carry a 5-year manufacturers warranty covering defects in materials or workmanship.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Industrial HDPE Pipe' category

|

ELEGANT POLYMERS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese